Turning visions into reality with our CNC Machines

CNC Milling –Angus 13070

The Angus 13070 CNC machine excels in high-precision machining with its robust, vibration-damping frame and advanced CNC control system. Its high-speed spindle and multi-axis capabilities allow for efficient material removal and the production of complex geometries. Features include an automatic tool changer, precision linear guideways, and an integrated cooling and chip management system, all designed to enhance productivity and ensure high-quality results. Safety features ensure secure operation throughout the machining process.

CNC ANGUS – 13070 Capabilities

X – 1300, Y – 700, Z -710

200 bed diameter

Positioning Repeatability X/Y/Z +_0.003

Positioning Accuracy X/Y/Z 0.008

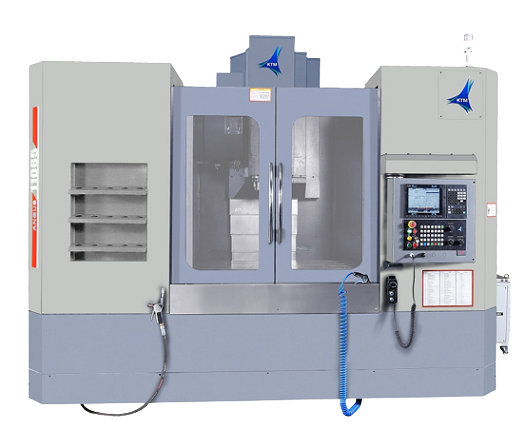

CNC Milling – KTM 13070

Use a multi-point rotating tool to remove material from the workpiece. Basic mills consist of a 3-axis system (X, Y and Z), which is still one of the most popular and widely used machining processes. In 3-axis machining, the workpiece remains fixed, and the rotating tool cuts along the x, y, and z axes. Meanwhile,

Milling machines are ideal for creating surfaces, grooves, pockets, and precise holes. With their 3-axis positioning, both conventional and CNC milling machines, as well as CNC milling centers, can produce complex spatial contours such as gearbox housings.

CNC KTM Milling Capabilities

- From KTM Techno Solutions, Axis Strokes, X – 1300, Y – 700, Z -760

- Positioning Repeatability X/Y/Z +_0.005

- Positioning Accuracy X/Y/Z 0.008 with Larger Bed movements

CNC Milling- Angus 11065

CNC Milling Machines are machine operated cutting tools that are programmed and managed by Computer Numerical Control (CNC) systems to accurately remove materials from a workpiece. The end result of the machining process is a specific part or product that is created using a Computer Aided Design (CAD) software. This process can control various complicated machinery, such as CNC milling machine, CNC lathe, CNC laser machine, water jet machine, electric discharge machine (EDM), to complete the three-dimensional cutting task. conduct cutting operations uses a rotating multi-point cutter (a milling tool), automatically on a rectangular workpiece using a program created in punched tape. NC lathes are used to conduct automatic turning and facing operations on cylindrical parts.

CNC Milling Capabilities

Dhruva Aerospace offers high-quality CNC milling services, expertly managing complex production runs across a wide range of materials and finishes. Whether you need low or high-volume production, our CNC milling machines ensure exceptional precision and detail, executing every job with pinpoint accuracy.

Capacity:

- X – 1100, Y – 650, Z -670

- VMC – Angus 11065

- 5 Axis Milling Machine : X – 1100, Y – 650, Z – 670 4 + 1 axis

- Positioning Accuracy : X/Y/Z 0.008

DG

CNC Turning- Sugan 11050

The Tsugami B0325V-III stands out for its versatility, capable of handling complex geometries with ease. Equipped with a high-precision spindle and advanced control systems, it offers unparalleled accuracy and repeatability, even in demanding production environments. The machine’s compact footprint and ergonomic design ensure ease of operation while maximizing floor space. With features such as live tooling, Y-axis capabilities, and efficient chip evacuation, the B0325V-III is engineered to deliver superior performance across a range of materials, making it an essential asset for manufacturers seeking to enhance productivity and quality in their turning operations.

EDM – Yuva 1050

The VMC 1050 features a rigid, heavy-duty cast iron structure that ensures excellent stability and vibration damping for high accuracy and superior surface finish quality. Equipped with a powerful spindle motor capable of speeds up to 10,000 RPM, it allows for fast and efficient material removal.

For greater accuracy and reliability at higher speeds, the VL-1050 is designed with a high-dynamic structure and rapid axis acceleration. Its broad base and heavy column enhance vibration damping and balance during heavy cutting operations. The broad table, supported by precision LM guideways, offers high load-carrying capacity. This series is ideal for high material removal from castings and forgings, making it perfect for die and mold applications.

Capacity:

- X – 600, Y – 450, Z -250

- Bed Size : X – 1000, Y – 500mm

- Max permissible load 1500 kg

Height Gauge- Trimos V7

The V7 are equipped with the revolutionary displacement handwheel allowing the user to choose either the manual or motorized displacement mode.

Measuring ranges 400 to 1800 mm

Simple and easy-to-use graphic interface

Electronically adjustable measuring force

Manual or motor-driven displacement

2d, programming, statistics

Vast range of accessories

All adjustments possible without tools

RS232 et USB interfaces

Wireless data transfer (optional)

Capabilities:

- 2 D Advanced Height Gauge

- Measuring Range 711 mm

- Max permissible errors, BMPE 2+ L (mm)/ 400, 2.5 +L (mm)/300

- Repeatability, RMPE (2s)